Paul Rivers

About me

SKILLS

Find A Solution

Robotics / Navigation & Control Solutions Negotiation / Communication Data Analysis / Research & Development Stakeholder Relationship Management Technology Integration Software Applications

Business Development

Strategy Formulation / Business Planning Market Expansion & Diversification Sales Contracts / Tendering International B2B / B2C Sales Account Management Distribution / Logistics

Team Leadership

Project Management Divestment / Mergers & Acquisitions Process Re-engineering / Automation Employee Development / Leadership Stakeholder Relationship Management Operational Management

My PRODUCTS / INVENTIONS / SOLUTIONS

Vaporline, Easy & Flexible Way to Upgrade Line Follower For Natural Feature Navigation. Patent GB1904550.9

Learn MoreArticles published in the media:

Automating Risk Management to Improve Employee Safety in Warehouses

Automating warehouse facilities has many recognised operational benefits – from increasing efficiency, improving productivity and becoming less reliant on the manual workforce. Yet, a common misconception of automation is that it can negatively impact employees' safety. Indeed, in Guidance Automation’s 2022 research, 64% of respondents said that safety concerns around physical accidents caused by automated systems were preventing them from implementing warehouse or manufacturing plant automation. Such findings demonstrate a lack of education around automation – as rather than being a barrier to deployment, businesses should consider automation’s capability to minimise health and safety risks a positive.

Read MoreAnnual Automation Report Reveals Industry cites Intralogistics Automation As ‘Critical’ For Success and Growth

The report looks to understand the 2022 market for Autonomous Mobile Robot technologies (AMRs) amongst companies that have a warehouse, fulfilment, production, or distribution operation – and how it has changed from the same research conducted in 2021. The research was conducted with the UK’s leading intralogistics technology decision makers and looked at the year-on-year differences, which included the industry’s change in time and expectations of implementing AMRs; the drivers and perceived barriers to implementing AMRs; and what businesses look for in an intralogistics automation vendor.

Read MoreNo Business is Too Small for Automation

There remain many misconceptions around implementing automation. Guidance Automation’s recent research identified the greatest perceived barriers to be the costs involved / budget constraints (76%), the need to up-skill staff (74%), and the belief that warehouse processes are too changeable (63%). But a further widespread myth is that a business may be ‘too small’ for automation. This is emphatically not the case.

Read MoreAutomation for All

Lights-out Ocado warehouses staffed by robots may appear a world away from the 20 person manufacturing company or family-run logistics operation, but that is no longer the case. Automation – including the use of autonomous mobile robots (AMR) – can play an important role in businesses of any size and it doesn’t have to come with a ridiculous price tag or disruption. Adding just one or two robots to the business can reduce the amount of time operatives spend walking around the warehouse, or allow individuals to concentrate on added value activities such as quality checking. It can add contingency, helping a business manage the current staffing shortfalls. Plus with the ability to rent robots – including by the hour – companies have access to an affordable resource on demand.

Read More2022 – The Year of Automation

Everyone is fed up of hearing about the pandemic and the catastrophic impact it has had on the world. But the fact is, although statistics confirm Covid-19 is waning, the rise of new variants including Omicron means the virus is still very much present and working its way through the population, continuing to leave its destruction behind it. This, combined with the effects of Brexit, have dragged UK businesses into unknown territory in a ‘sink or swim’ style scenario. Many businesses have folded, thousands of jobs have been lost, but there is an upside to this – many have managed to ride the wave and come out the other side with a stronger, more resilient business model that will drive them forward despite uncertain times.

Read MoreFuture Proofing Following COVID-19: The Key is Embracing Automation

Most businesses suffered, some businesses failed, but for those who survived the ravages of the pandemic, what lessons have been learned and, perhaps more importantly, what plans are now in place to make businesses more resilient moving forward? History is littered with pandemics; following bird flu & swine flu, and COVID-19 has arguably been the worst since the Spanish flu. But what next? Another pandemic is inevitable at some point in the future. And on top of that, there is seasonal flu - absent last year, but could be making a strong comeback this year - preying on those of us who have been socially distanced and now less prepared to fight off illness.

Read MoreSurvive and Thrive During Peak Retail with Automation

The retail industry has had a rollercoaster of a year, from the high street being closed for months on end, to e-commerce operators managing the acceleration of demand during lockdown. Now open and back in business, both online and offline retailers are feeling the pressures ahead of the busy shopping seasons, with Black Friday and Christmas just around the corner.

Read MoreA new era of accelerated Intralogistics Automation

The unfortunate mix of Brexit and Covid-19 has had a tremendous impact on businesses around the world forcing them to re-evaluate how they operate in uncharted territory. This disruption has presented many challenges over the past 18 months but fortunately, many opportunities, with unprecedented e-commerce growth during Lockdown providing new customers and unexpected revenue. Manufacturing and logistics businesses in particular have entered a new era where intralogistics automation and Autonomous Mobile Robot Technologies (AMRs) are becoming commonplace but is this our future or are we placing ourselves at risk by putting too much trust in technology too soon?

Read MoreDigitally Transforming Businesses with Robotic Process Automation

Businesses across all industries around the world have had to reconsider their infrastructure, processes and workforces as a result of the pandemic. With additional pressures to meet increased customer demand while restricted by Covid-induced social distancing measures, organisations have had to adapt in order to survive, with many turning to technology to do this. According to recent research, almost half of existing jobs could be automated within the next generation due to technology integration and the acceleration of automation. Here I highlight how Robotic Process Automation (RPA) is an area of technology that will continue to drive business transformation, but only if implemented correctly.

Read MoreInvesting in the Future: Grow Your Own Robot

Automation can be seen as a complex area, and it is yet to reach its full potential – the challenge remains for robots to accurately and efficiently ‘pick’ items – but this shouldn’t steer organisations away from making that initial investment. Instead, by incrementally deploying new technologies and starting to innovate your processes, that can be scaled as times goes on, businesses can future-proof their investment and continue to reap the benefits from innovation time and time again.

Read MoreThe future of bespoke automation

Automation is clearly a key component of the future, it already makes up a significant part of supply chains and factories today; from robotic X-ray machines in hospitals to pallet trucks, parking lots, baggage handling and even stage scenery automation within theatres. There is a rapid expansion happening in the automation industry, especially as bespoke vehicles can be created for businesses to leverage specific and measurable benefits through qualified consultation that doesn’t break the bank. Paul Rivers, Managing Director at Guidance Automation discusses what the future holds for automation, and how for businesses to gain the most benefit from these technologies, they must look to deploy a bespoke solution that aligns precisely with their processes, goals and workforce in order to fully reap the benefits.

Read MoreA Tearoom for robots

Robotics is being used in a variety of industries and applications, with new use cases being defined almost daily. For example, the rapid growth of ecommerce over the years is showing no signs of slowing, with online sales due to account for over 50% of retail sales over the next decade. Within the UK, online spend is predicted to increase 29.6% by 2024, with more than 50% of UK consumers now choosing to shop online over the high street. As ecommerce continues to expand, the demand for warehouse workers is growing at a rapid rate, creating an even greater need for automation.

Read MoreProcess, People, Technology

There has been much written about the benefits that automation can unlock for businesses, but too often businesses think they need to jump in at the deep end and deploy automation technology straight away, hoping it will solve the problems they are experiencing. But how will a process optimised for a manual workforce perform with automation – such as an Automated Guided Vehicle (AGV)? How will people respond when their day to day roles change? If the aim is to improve efficiency and productivity, technology is just one part of the overall solution.

Read MoreAutomation - No need to rip and replace

The concept of full automation could be daunting, especially considering the cost, time and disruption that go into building a brand new factory or warehouse – this just isn’t a viable option for a large proportion of businesses. But full automation isn’t necessarily an appropriate strategy; there is no need to revolutionise the entire facility to achieve significant productivity and efficiency improvements. As Dr Paul Rivers, CEO, Guidance Automation explains, tactical automation can be strategic.

Read MoreAutomation as a complement, not a replacement of the human workforce

Smart automation has the potential to deliver great economic benefits, but there remain many concerns that the use of AI and robotics could displace many existing jobs. With the desire for automation increasing and more sectors looking to deploy the technology, particularly within manufacturing, logistics and distribution, it’s important to understand how automation can augment the workforce, rather than replacing it.

Read MoreAcceleration of the Automation Evolution

As with most sectors, as soon as the pandemic first hit, organisations went into shock. With lockdown measures in place, how could they keep up business continuity? How could they strategise effectively with so much uncertainty? How would global disruptions affect supply chains? Businesses had to rapidly adapt and deploy numerous damage control measures. In several industries, however, it was clear that automation of particular functions could pave the way for an accelerated return to as close to normalcy as possible. Manufacturing, for example, has the potential to involve multiple automated roles, providing a solution to the social distancing challenge, as well as underpinning flexibility for labour needs.

Read MoreEmbracing automation and robots in industry

The future lies in the innovation of industry; efficiency and automation are the key buzzwords of 2020 as Covid-19 pressure drives businesses to seek new and unique ways to achieve more with less, and counter those slimming margins. Within warehousing, logistics and picking and packing for e-commerce for example, there’s been a rapid uptake over recent times of automated processes and the added support of robotics. Autonomous vehicles and effective autonomous transport solutions for instance can contribute a significant improvement in throughput efficiency and error reduction for e-fulfilment applications. However the UK has been historically slow with adoption as it faces reservations.

Read MoreRoutes to Professional Success in Automation

The jobs of tomorrow require skilled and digitally-enabled employees, as they are the key to business success and international economic development. However, the latest IRF report on World Robotics highlighted how far behind the UK is in terms of automation compared to its international rivals, which is compounded by a skills shortage in the qualifications needed to drive automation. Why does this gap exist and what is the need for further collaboration between government and higher education establishments to offer appropriate courses and resources for students – and in turn, businesses – to prepare for the future automated world.

Read MoreQuotes

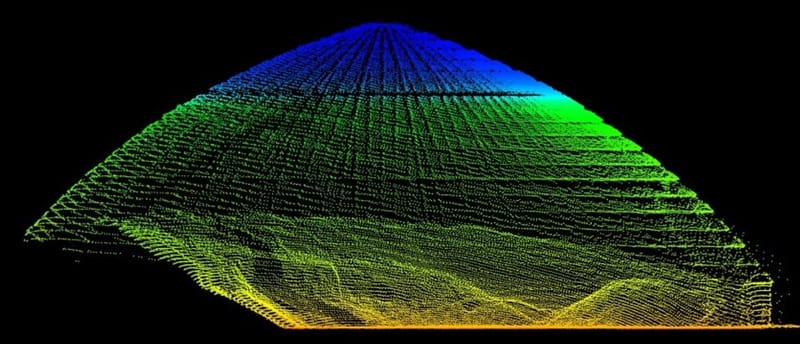

IMAGE STORY

Set all of this in the context of my surname and hence the water theme. The riding through a wave represents the challenges of life and heading along the waterway (path) to these planets. There is chance of rough times if the wave crashes. The water in the centre is calm and there are many calm ripples. These are good memories of life so far which will gently remind me of the past and how I have got here.

Whichever planet I chose, there will always be three more planets to venture towards in the future. We should all be aspiring to move forward and keep the experiences flowing.